High Temperature Paddlewheel Flow Sensors - JT-123

We are Manufacturer, Supplier, Exporter of High Temperature Paddlewheel Flow Sensors / Transmitters and Our setup is situated in Pune, Maharashtra, India. City wise / country wise Channel Partnership enquiries also solicited all over the world. Few of our concepts have already awarded patents in India and many new designs are applied for the patent, recently.

High Temperature Insertion Paddle Wheel Flow Sensor

GENERAL DESCRIPTION

JT-123 is paddle Wheel type SS body with Flameproof Enclosure Flow sensor suitable for High Temperature liquid application. It is Unique combination of ROBOST design and easy to use flow sensor. VATS' make flame proof Flow sensor use for chemicals in various industries with important features like Stainless Steel Rotar and high temparature and pressure application. With proper installations JT-123 sensor can be installed in wide range of pipe sizes. Variety of materials is available in installation fittings in SS. These fittings include Tees, with specific Weld Ends, Thread Ends or Flange Ends and Weldon Adaptor.

• Use of filter before Flowmeter is necessary

• Straight Run conditions given in manual must be maintain while

installation

FEATURES

- Flameproof Enclosure

- Harsh Industrial Application.

- Four bladed paddle for optimal performance.

- Dynamic range with virtually no pressure drop.

- Wide choice of installation Fittings.

- Lower installation and maintenance cost.

- Stainless Steel Rugged Rotor Suitable for High

- Temperature Application.

TECHNICALS

Technical Data

- Velocity: 1 To 5 m/s

- Linearity: +/- 1 % OF Full scale

- Repeatability: +/- 0.5 % of Full scale

- Temperature Range: 125°C

- Viscosity: Upto 20cp

- Pressure Range: Upto 25 Bar

Electrical Connection Ratings

- Power Supply: 12-24 V DC +/-15%

- Consumption: < 30 mA

- Output Voltage: 12-24 V DC

- Output Signal: NPN / PNP

- Cable Type: 3core PTFE inner with PVC Coating

Material

- Sensor Body: SS316

- Paddle: SS

- PIN: T.C.

- Gasket: PTFE

- Bearing Bush: PEEK

- Protection Rating: IP-65

APPLICATIONS

- Water Treatment

- Cooling

- Construction

- Oil

- Power

- Textiles

- Various Chemicals

- Diesel / Petrol

- Boiler

- An Applications Haveing High Pressure.

LINE SIZE SELECTION CHART

| Pipe size(NB) | 15 | 25 | 40 | 50 | 65 | 80 |

| Min flow M³/Hr | 0.2 | 0.8 | 1.9 | 3.5 | 5.8 | 7.5 |

| Maxflow M³/Hr | 2.1 | 8.0 | 19 | 35 | 58 | 75 |

| Pipe size(NB) | 100 | 125 | 150 | 200 | 250 | 300 |

| Min flow M³/Hr | 14 | 22 | 31 | 56 | 87 | 126 |

| Maxflow M³/Hr | 140 | 220 | 310 | 560 | 870 | 1260 |

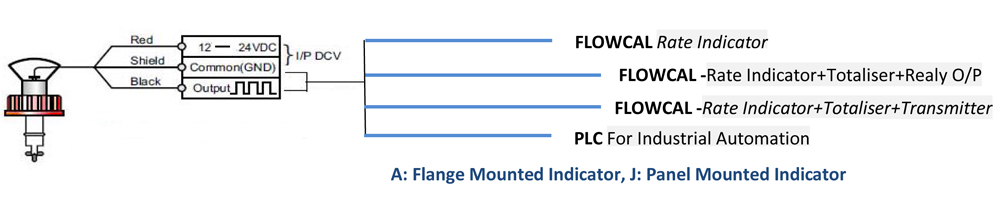

ELECTRICAL WIRING

Variety of Electronic Readers cum controllers are available.

For Battery Operated Active Sensor please contact the Factory.

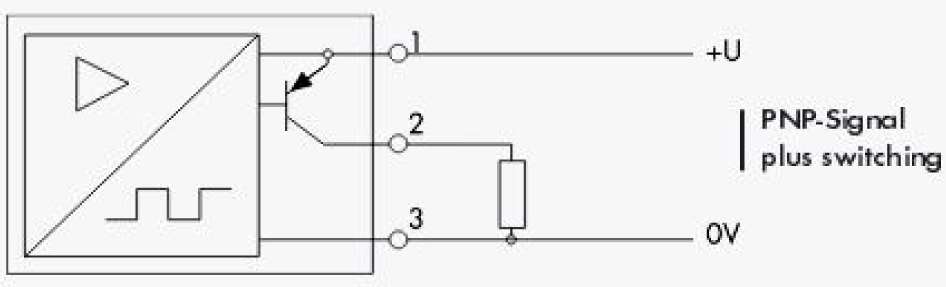

Connection : PNP Switching

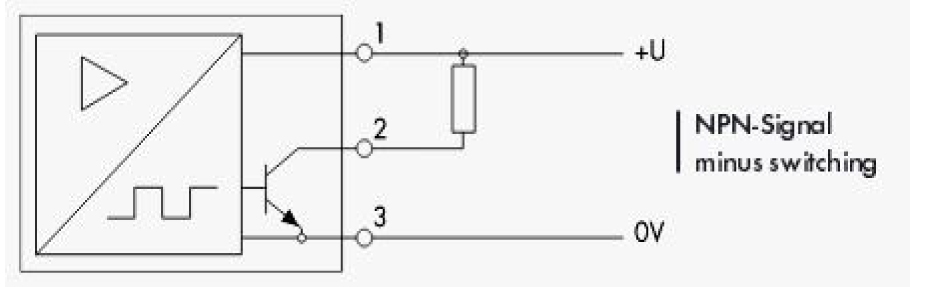

Connection : NPN Switching

MECHANICAL

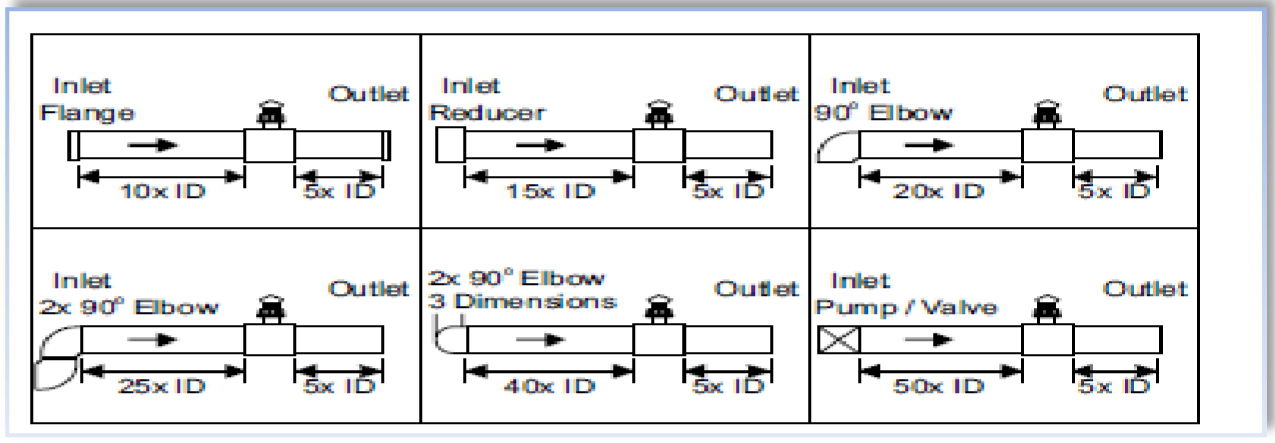

Straight inlet and outlet distances that must be maintained when installing fittings in pipe lines in order to achieve turbulent flow conditions. The most important layouts that could lead to turbulence in the flow are shown below, together with mentioned minimum and inlet and outlet distances. These insure turbulent, problem-Free measurement conditions at the measurement point. For more Installation guidelines please refer manual. for best results Reynolds number (R) is greater than 5000 especially for viscous liquids. to Calculate R use following formula

NOTE :

1. In Vertical Piping only Upstream flow is recommended.

2. Flow Meter should be installed before valve.

3. Y type strainer is must for recommend result.