Flow Transmitters / Batch Controllers - Flowcal

We are Manufacturer, Supplier, Exporter of Flow Transmitters / Flow Batch Controllers / Water Batch Controllers / Batch Controllers / Flow Batchers and Our setup is situated in Pune, Maharashtra, India. City wise / country wise Channel Partnership enquiries also solicited all over the world. Few of our concepts have already awarded patents in India and many new designs are applied for the patent, recently.

GENERAL DESCRIPTION

These electronic flow monitor are high speed micro - controller based units with a high resolution OLE Ddisplay. By using front membrane keypad, we can view / program different parameters. It is a Digital Rate Indicator and Totalizer, 4-20 mA, RS 485, relay suitable for VATS sensors or others giving pulse output of 400 Hz max. We can read the flow rate in LPH, M3 / Hr, LPM, GPM and corresponding Total reading in Liter or M3 and Gallon .Our IP 65 grade enclosures make our flow meter versatile on both Panel & Field uses Along with these two consecutive displays these monitors also have relays to operate in various modes.

• Use of filter before Flowmeter is necessary

• Straight Run conditions given in manual must be maintain while

installation

FEATURES

- Advance Technology and simplicity.

- Protection Structure IP65

- Password Protected Meter.

- Display Total + Flow Rate + relay + 4-20 mA + RS 485 output.

TECHNICALS

Technical Data

- Function: Totalizer +Flow Rate +4-20 mA + RS485 + relay

- Accuracy: +/- 2% of Full Scale

- Repeatability: +/- 0.5 % of full range

- Mounting: Field / Panel

Electrical Connection Ratings

- Power Supply: 230 V AC +/-10%, 50 Hz Meter

- Input: From VATS Sensor

- Display: O LED

- METER SIZE: 91mm x 91mm x 62mm

Material

- Housing: Poly Carbonate

- Protection: IP-65

- Weatherproof Enclosure

APPLICATIONS

- Water Treatment

- Agriculture

- Construction

- Paper and Pulp

- Food and Beverages

- Waste Water

- Power

- Textiles

Calibration

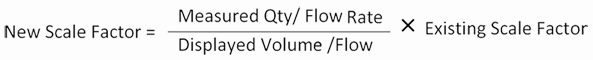

Scale factor : Scale factor is a value, meaning amount of the liquid in engineering unit to one pulse generated by sensor.

Recalibration : Suppose actual total is 10 liters. But indicate valve on display is 9.8 liters.

Points And Precautions To Be Noted

Ensure proper connection of mains ,wrong connection may spoil the meter. While extending the cable, use recommended type only, with proper insulation. Avoid noise interference. Do not pass the sensor wire parallel to power cable. If this is unavoidable-pass the sensor cable through noise protected tray.

Straight Run condition given in manual must be maintain while installation Use of filter before Flow meter is necessary Flow must be full bore constant i.e. pumping pressurized flow. For vertical installation only upstream flow is recommended. Flow Meter should be installed before valve. Y type strainer is must for recommend result. Flow rate range should match as per our given line size & flow rate range selection table.